Company clear values

COMPANY CULTURES: VISION:We aim to become a global high-end precision hardware cold extrusion service provider and can continue to contribute unique value, worthy of long-term trust as partners in China. MISSION:We focus on and deeply cultivate the precision cold extrusion field to solve the difficulties and pain points of the industry and customers as our mission. Also we continue to innovate, join the global high-end manufacturing industry chains, and promote high-quality "Made in China" hardware to the world VALUES: *Quality first *supreme service *honest and pragmatic *customer satisfaction

We focus on the leader in precision cold extrusion process and solutions to reduce manufacturing costs

STANDARD METAL, we are professional solutions provider who focus on hardware consecutive precision cold extrusion technology to solve the industry problems of high cost, low efficiency, difficult processing of high-tech hardware manufacturing.

Technical Features Advantages

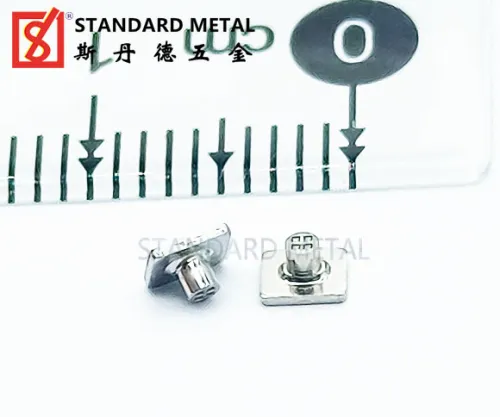

Technical Features: 1). High precision molding, fast speed, parts tolerance can be tested within +/ -0.02mm. 2). One time molding without other supporting process. 3). Truly optimize the cost, applicable to Invar, Kovar, copper, iron, nickel, aluminum, stainless steel and other raw materials which are malleable under HV220 hardness degrees can be completed into extrusion molding. STD really solves the angle collapse problems in cold pier and stamping process

Related Products

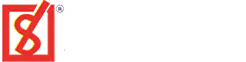

More items about precision fe-ni alloy processing

We Have The Best Solutions for Your Business

STANDARD METAL has a number of independent intellectual property rights included 12 domestic and international invention patents.

We mainly focus on optical communication, car automotive sensors, industrial automation, precision medical equipments, aviation industrial automatic control hardware, military packaging hardware, consumer electronics hardware and other applications. STD is using high-technology, unique innovation and modern process management to provide highly competitive products and offer professional services to meet customer needs.

Precision Fe-Ni Alloy Processing Physical Properties Sealing Alloy

These include other Fe-Ni grades, Fe-Ni-Co and Fe-Ni-Cr alloys. A full range of alloys has been produced in relation to major glasses supplied by major manufacturers including Schott, Corning, NEG and Ashai. These glasses for electronics are selected for specific physical, chemical or optical properties, and the selection of the associated sealing metal depends on the glass and sealing type (matching or compression).

Two broad categories of precision fe-ni alloy processing

Low expansion alloys, Invar and N42 alloys, are widely used in the manufacture of electronic components in integrated circuits, and (ii) hermetic alloys, such as Fe-Ni-Cr and Fe-Ni-Co alloys, have been produced for use in various temperature ranges optical components, especially associated with specific glasses.

precision fe-ni alloy processing other application areas

Other fields of application, such as telecommunications, aerospace engineering, cryogenic engineering (LNG tankers), etc., require high dimensional stability with temperature, or in combination with other materials such as glass, ceramics or composites.

Advantages of precision fe-ni alloy processing

Thermal characteristics of Fe-Ni Invar is closer to glass and ceramics and thus were useful for glass-metal and ceramic to metal joints. This alloy is used in containers used for transport liquid natural gas on tankers as the alloy has minimum cryogenic shrinkage.

User Reviews

What users say about Robot

Frequently Asked Question

Do you have any question?

It has been observed that Fe 1x Ni x alloys are soft ferromagnetic materials for all compositions with very high curie temperature. The Fe metal is of bcc structure (α phase) whereas the Ni metal is of fcc structure (γ phase). The alloy series exhibits a structural transition from bcc to fcc at around Ni concentration of 25% .

The Fe–Ni–Ti alloy system has been evaluated, together with Fe–Ni and Fe-Ti binary subsystems, to provide reliable information for applications and in view of a thermodynamic modelling of the system.

The Fe metal is of bcc structure (α phase) whereas the Ni metal is of fcc structure (γ phase). The alloy series exhibits a structural transition from bcc to fcc at around Ni concentration of 25%