Features

Why Choose Robot?

Company clear values

COMPANY CULTURES: VISION:We aim to become a global high-end precision hardware cold extrusion service provider and can continue to contribute unique value, worthy of long-term trust as partners in China. MISSION:We focus on and deeply cultivate the precision cold extrusion field to solve the difficulties and pain points of the industry and customers as our mission. Also we continue to innovate, join the global high-end manufacturing industry chains, and promote high-quality "Made in China" hardware to the world VALUES: *Quality first *supreme service *honest and pragmatic *customer satisfaction

We focus on the leader in precision cold extrusion process and solutions to reduce manufacturing costs

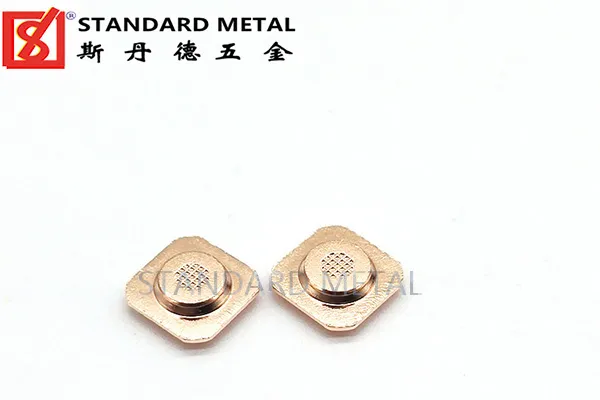

STANDARD METAL, we are professional solutions provider who focus on hardware consecutive precision cold extrusion technology to solve the industry problems of high cost, low efficiency, difficult processing of high-tech hardware manufacturing.

Technical Features Advantages

Technical Features: 1). High precision molding, fast speed, parts tolerance can be tested within +/ -0.02mm. 2). One time molding without other supporting process. 3). Truly optimize the cost, applicable to Invar, Kovar, copper, iron, nickel, aluminum, stainless steel and other raw materials which are malleable under HV220 hardness degrees can be completed into extrusion molding. STD really solves the angle collapse problems in cold pier and stamping process

We Have The Best Solutions for Your Business

STANDARD METAL has a number of independent intellectual property rights included 12 domestic and international invention patents.

We mainly focus on optical communication, car automotive sensors, industrial automation, precision medical equipments, aviation industrial automatic control hardware, military packaging hardware, consumer electronics hardware and other applications. STD is using high-technology, unique innovation and modern process management to provide highly competitive products and offer professional services to meet customer needs.

Introduction to precision brass processing

Brasses with a copper content greater than 63% are the most ductile of any copper alloy and are shaped by complex cold forming operations. Brass has higher malleability than bronze or zinc. The relatively low melting point of brass and its fluidity make it a relatively easy material to cast. Brass can range in surface color from red to yellow to gold to silver depending on the zinc content.

Some of the common uses for brass alloys include costume jewelry, locks, hinges, gears, bearings, hose couplings, ammunition casings, automotive radiators, musical instruments, electronic packaging, and coins. Brass and bronze are common engineering materials in modern architecture and primarily used for roofing and facade cladding due to their visual appearance.

Featured Products

Collection about Robot

User Reviews

What users say about Robot

Frequently Asked Question

Do you have any question?

45 Colt Brass. Originally designed for use with blackpowder, the .45 Colt is one of the most powerful, commonly available handgun cartridges when loaded with smokeless powder. Our .45 Colt brass has been tested to .44 Magnum pressures in gun systems suitable for such loads. *New brass may require neck sizing for use with .452" and smaller bullets.

The fatigue strengths of bronze and brass are given as ranges in Table 1, as there are many alloys of each metal. Bronze generally has a higher fatigue resistance than brass, which can be seen by comparing the lower bound of their fatigue strength ranges.

In summary, brass casings deliver: Easy manufacturing, resulting in an affordable price Consistent expansion in the chamber Smooth feeding and case extraction Corrosion resistance

Our updates and blog posts

Are simple miniature metal punches easy to make?precision-brass-processing

{keyword}We provide related products about if you are interested in , please contact us.

How to machine Kovar parts with precise machining efficiency?precision-brass-processing

{keyword},We provide related products about if you are interested in , please contact us.

Standard develops cold extrusion processing technology into an automated big moveprecision-brass-processing

{keyword},We provide related products about if you are interested in , please contact us.