Company clear values

COMPANY CULTURES: VISION:We aim to become a global high-end precision hardware cold extrusion service provider and can continue to contribute unique value, worthy of long-term trust as partners in China. MISSION:We focus on and deeply cultivate the precision cold extrusion field to solve the difficulties and pain points of the industry and customers as our mission. Also we continue to innovate, join the global high-end manufacturing industry chains, and promote high-quality "Made in China" hardware to the world VALUES: *Quality first *supreme service *honest and pragmatic *customer satisfaction

We focus on the leader in precision cold extrusion process and solutions to reduce manufacturing costs

STANDARD METAL, we are professional solutions provider who focus on hardware consecutive precision cold extrusion technology to solve the industry problems of high cost, low efficiency, difficult processing of high-tech hardware manufacturing.

Technical Features Advantages

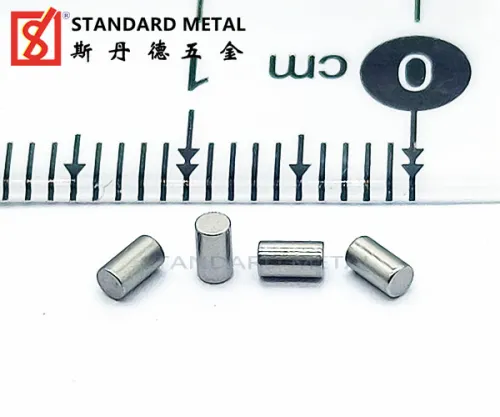

Technical Features: 1). High precision molding, fast speed, parts tolerance can be tested within +/ -0.02mm. 2). One time molding without other supporting process. 3). Truly optimize the cost, applicable to Invar, Kovar, copper, iron, nickel, aluminum, stainless steel and other raw materials which are malleable under HV220 hardness degrees can be completed into extrusion molding. STD really solves the angle collapse problems in cold pier and stamping process

Related Products

More items about micro precision cold extrusion part

We Have The Best Solutions for Your Business

STANDARD METAL has a number of independent intellectual property rights included 12 domestic and international invention patents.

We mainly focus on optical communication, car automotive sensors, industrial automation, precision medical equipments, aviation industrial automatic control hardware, military packaging hardware, consumer electronics hardware and other applications. STD is using high-technology, unique innovation and modern process management to provide highly competitive products and offer professional services to meet customer needs.

Purpose of Micro Precision Cold Extrusion Partd

Micro precision cold extrusion part applied to STANDARD Metal focuses on optical communication, car automotive sensors, industrial automation, precision medical equipments, aviation industrial automatic control hardware, military packaging hardware, consumer electronics hardware and other applications.

The main contradiction of micro precision cold extrusion part

The micro precision cold extrusion is deformed in the cold state of the metal, and is deformed under a strong three-way compressive stress state, so the deformation resistance is relatively large. For example, carbon steel parts are processed by deep drawing method.

What are the advantages of micro precision cold extrusion continuous die processing hardware?

The advantages of continuous die cold extrusion processing of micro precision cold extrusion parts:

1. Fast processing speed, can process more than 100 parts per minute

2. Save materials, and the material utilization rate is more than 65%

3. The strength of the product is higher, and the strength of the forged parts is more than 3 times that of the raw material

4. Good plasticity, CNC easy-to-stick material is exactly the material that is easy to process by continuous die cold extrusion

User Reviews

What users say about Robot

Frequently Asked Question

Do you have any question?

Copper is an excellent metal for cold forging since it is very ductile and malleable. It can be shaped, bent, or pulled with little force and produces parts that are corrosion and rust resistant. Aluminum is a non-ferrous metal that is extremely light with a low density.

It can provide power over several rotations but has to idle in order to regain power from its motor before it can continue its cycles. Of the many varieties of cold forging equipment, the most common types are hydraulic and pneumatic, because they take up less room, can supply varied amounts of force, and are programmable.

In contrast, cold forging is typically a single-pass forming process that deforms the existing material into the desired shape. Depending on part-specific parameters, the time savings per piece can deliver major productivity improvements.