Company clear values

COMPANY CULTURES: VISION:We aim to become a global high-end precision hardware cold extrusion service provider and can continue to contribute unique value, worthy of long-term trust as partners in China. MISSION:We focus on and deeply cultivate the precision cold extrusion field to solve the difficulties and pain points of the industry and customers as our mission. Also we continue to innovate, join the global high-end manufacturing industry chains, and promote high-quality "Made in China" hardware to the world VALUES: *Quality first *supreme service *honest and pragmatic *customer satisfaction

We focus on the leader in precision cold extrusion process and solutions to reduce manufacturing costs

STANDARD METAL, we are professional solutions provider who focus on hardware consecutive precision cold extrusion technology to solve the industry problems of high cost, low efficiency, difficult processing of high-tech hardware manufacturing.

Technical Features Advantages

Technical Features: 1). High precision molding, fast speed, parts tolerance can be tested within +/ -0.02mm. 2). One time molding without other supporting process. 3). Truly optimize the cost, applicable to Invar, Kovar, copper, iron, nickel, aluminum, stainless steel and other raw materials which are malleable under HV220 hardness degrees can be completed into extrusion molding. STD really solves the angle collapse problems in cold pier and stamping process

Related Products

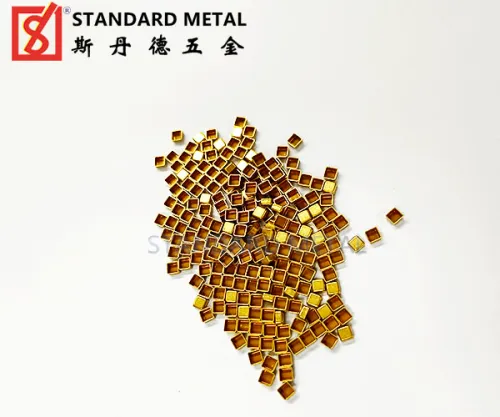

More items about precision oxygen-free copper processing

We Have The Best Solutions for Your Business

STANDARD METAL has a number of independent intellectual property rights included 12 domestic and international invention patents.

We mainly focus on optical communication, car automotive sensors, industrial automation, precision medical equipments, aviation industrial automatic control hardware, military packaging hardware, consumer electronics hardware and other applications. STD is using high-technology, unique innovation and modern process management to provide highly competitive products and offer professional services to meet customer needs.

Precision oxygen copper processing high heat capacity

Due to the higher conductivity, OFC copper wire does not heat up as quickly as other metals such as aluminum. Therefore, they also have excellent thermal strength and thermal conductivity. Industry relies heavily on them in high temperature applications such as induction furnaces.

Excellent resistance to hydrogen embrittlement for precision oxygen-free copper machining

Oxygen-free copper has excellent resistance to hydrogen embrittlement that occurs in wet electrochemical environments. Due to its malleability, solderability and lack of reactivity in oxygen-free water, Finland even uses copper cans to store nuclear waste inside packaging plants.

Precision oxygen-free copper processing for excellent electrical conductivity

During the manufacture of OFC, Precision oxygen-free copper processing is processed in the presence of carbon to remove any oxygen present. High purity, coupled with the absence of oxygen, allows more current to pass through conductors of the same size. Therefore, OFCs are used exclusively for battery cables, induction coils and space heaters.

User Reviews

What users say about Robot

Frequently Asked Question

Do you have any question?

The copper refining process is conducted in an atmosphere lacking oxygen. This could be a vacuum, an inert atmosphere or a reducing environment. Is 100% oxygen-free copper possible? Almost but not quite. It’s possible to achieve extremely pure copper, which qualifies it to be called oxygen-free high conductivity copper (OFHC).

Conductivity and power dissipation are the two most important characteristics of oxygen-free copper (or simply Etp). The higher the purity, the lower the conductivity, but the higher the power dissipation also.

Despite what some manufacturers claim, Oxygen Free Copper (OFC) won’t improve your sound quality at least not over any other type of wire capable of transferring the same amount of current.