Company clear values

COMPANY CULTURES: VISION:We aim to become a global high-end precision hardware cold extrusion service provider and can continue to contribute unique value, worthy of long-term trust as partners in China. MISSION:We focus on and deeply cultivate the precision cold extrusion field to solve the difficulties and pain points of the industry and customers as our mission. Also we continue to innovate, join the global high-end manufacturing industry chains, and promote high-quality "Made in China" hardware to the world VALUES: *Quality first *supreme service *honest and pragmatic *customer satisfaction

We focus on the leader in precision cold extrusion process and solutions to reduce manufacturing costs

STANDARD METAL, we are professional solutions provider who focus on hardware consecutive precision cold extrusion technology to solve the industry problems of high cost, low efficiency, difficult processing of high-tech hardware manufacturing.

Technical Features Advantages

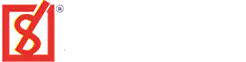

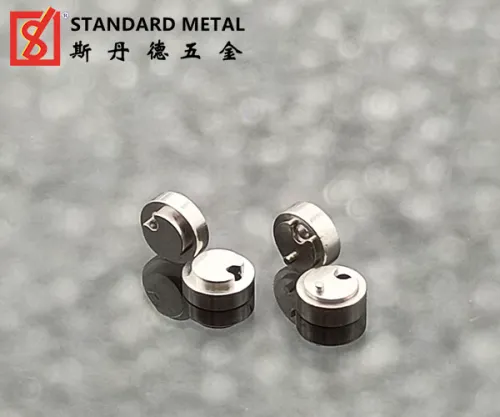

Technical Features: 1). High precision molding, fast speed, parts tolerance can be tested within +/ -0.02mm. 2). One time molding without other supporting process. 3). Truly optimize the cost, applicable to Invar, Kovar, copper, iron, nickel, aluminum, stainless steel and other raw materials which are malleable under HV220 hardness degrees can be completed into extrusion molding. STD really solves the angle collapse problems in cold pier and stamping process

Related Products

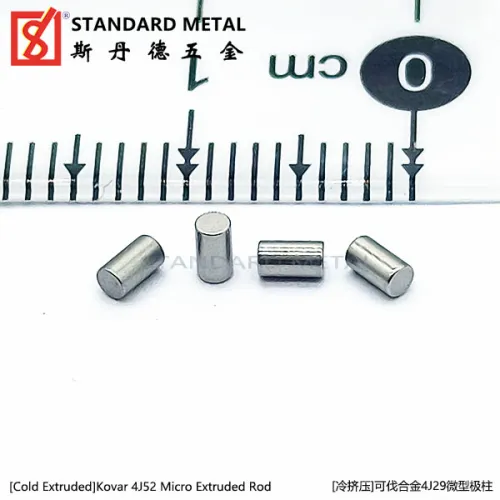

More items about cold extrusion kovar alloy processing

We Have The Best Solutions for Your Business

STANDARD METAL has a number of independent intellectual property rights included 12 domestic and international invention patents.

We mainly focus on optical communication, car automotive sensors, industrial automation, precision medical equipments, aviation industrial automatic control hardware, military packaging hardware, consumer electronics hardware and other applications. STD is using high-technology, unique innovation and modern process management to provide highly competitive products and offer professional services to meet customer needs.

What can cold extrusion kovar alloy processing be used for?

Cold extrusion kovar alloy processing is also used in many other products such as microwave tubes, transistors, diodes, power tubes, X-ray tubes, and virtually anything that requires glass-to-metal (or ceramic) sealing. It is also used in integrated circuits such as flat packs and dual in-line packages.

What are the uses of cold extrusion kovar alloy processing?

From the color of the interface, gray, gray-blue or gray-brown indicates a good seal, and black indicates that the alloy is over-oxidized and the bond is weak. Cold extrusion kovar alloy processing is suitable for glass/ceramic metal sealing of scientific instruments such as vacuum tubes (light bulbs), microwave tubes, X-ray and microwave tubes, transistors and diode integrated circuits.

What are the advantages of cold extrusion kovar alloy processing?

The main advantages of cold extrusion kovar alloy processing include:

1. Very low coefficient of thermal expansion (CTE)

2. Metal stamping capacity

3. Advanced dimensional stability

User Reviews

What users say about Robot

Frequently Asked Question

Do you have any question?

Since Kovar Alloy is tough and versatile, while employing extensive quality controls throughout UNS K94610 alloy’s manufacturing process to ensure uniform physical and mechanical properties for ease in deep drawing, stamping and machining are consistently achieved.

If we take for example a traditional tube light which is commonplace in many workplaces we can then look at how Kovar works in real life situations. We all know from accidentally touching a tube lightbulb that the glass can become extremely hot very quickly. Creating the required lighting using electricity creates immense heat which very quickly transfers to the glass.

Whereas Invar is designed to have a very low coefficient of thermal expansion (CTE) and is thus “in-variant” to temperature, Kovar is designed to be “covariant”. It was designed so that its CTE closely matched that of borosilicate glasses but it is a good match for some alumina ceramics as well