Company clear values

COMPANY CULTURES: VISION:We aim to become a global high-end precision hardware cold extrusion service provider and can continue to contribute unique value, worthy of long-term trust as partners in China. MISSION:We focus on and deeply cultivate the precision cold extrusion field to solve the difficulties and pain points of the industry and customers as our mission. Also we continue to innovate, join the global high-end manufacturing industry chains, and promote high-quality "Made in China" hardware to the world VALUES: *Quality first *supreme service *honest and pragmatic *customer satisfaction

We focus on the leader in precision cold extrusion process and solutions to reduce manufacturing costs

STANDARD METAL, we are professional solutions provider who focus on hardware consecutive precision cold extrusion technology to solve the industry problems of high cost, low efficiency, difficult processing of high-tech hardware manufacturing.

Technical Features Advantages

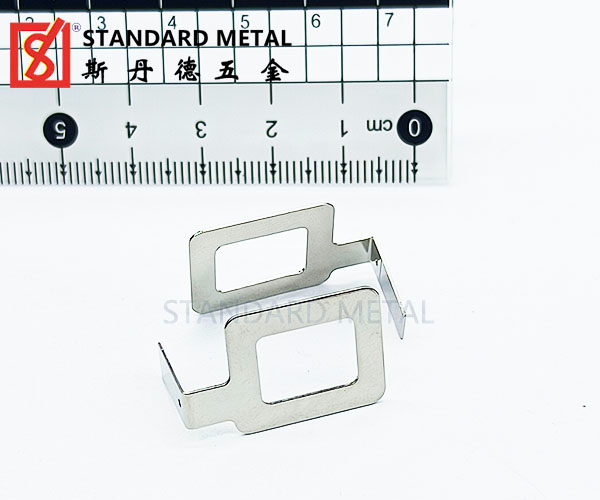

Technical Features: 1). High precision molding, fast speed, parts tolerance can be tested within +/ -0.02mm. 2). One time molding without other supporting process. 3). Truly optimize the cost, applicable to Invar, Kovar, copper, iron, nickel, aluminum, stainless steel and other raw materials which are malleable under HV220 hardness degrees can be completed into extrusion molding. STD really solves the angle collapse problems in cold pier and stamping process

We Have The Best Solutions for Your Business

STANDARD METAL has a number of independent intellectual property rights included 12 domestic and international invention patents.

We mainly focus on optical communication, car automotive sensors, industrial automation, precision medical equipments, aviation industrial automatic control hardware, military packaging hardware, consumer electronics hardware and other applications. STD is using high-technology, unique innovation and modern process management to provide highly competitive products and offer professional services to meet customer needs.

Precision stamping manufacturing process

Precision stamping includes a variety of sheet-metal forming manufacturing processes, such as punching using a machine press or stamping press, blanking, embossing, bending, flanging, and coining. This could be a single stage operation where every stroke of the press produces the desired form on the sheet metal part, or could occur through a series of stages.

Advantages of precision stamping

As a metal fabrication method, precision metal stamping offers numerous benefits, including:

High-speed production.Precision metal stamping is highly automated and efficient, which reduces production time and allows for superior accuracy and repeatability.Exceptional accuracy.Precision metal stamping tolerances are exceptionally high, which results in components of superior and consistent quality.

Cost-effective. Precision metal stamping is highly efficient, requires minimal labor, and produces little material waste, thereby improving production efficiency and lowering overall production costs.

The role of precision stamping

Precision stamping is a fast and cost-effective solution for manufacturing large quantities of sheet metal stamping parts. There are three major precision stamping applications currently in use at factories across the globe: micro-precision stamping, intricate precision metalwork, and prototype design.

User Reviews

What users say about Robot

Frequently Asked Question

Do you have any question?

Precision stamping machines are useful in a variety of applications, especially those involving three-dimensional designs, lettering, or other surface engraving features.

Precision stamping, which may include progressive die stamping and single-step processes, offers several benefits, particularly for high-volume projects. Lower costs: When doing large projects consisting of multiple units of the same part, precision stamping has a lower cost due to less labor for manufacturing additional units.

1. Blanking and punching Blanking and punching are the processes to separate the blanks 2. Bending is to make the workpiece obtain various shapes of corners. 3. Deep drawing is the process of making flat blanks into cup-shaped or box-shaped parts.