Company clear values

COMPANY CULTURES: VISION:We aim to become a global high-end precision hardware cold extrusion service provider and can continue to contribute unique value, worthy of long-term trust as partners in China. MISSION:We focus on and deeply cultivate the precision cold extrusion field to solve the difficulties and pain points of the industry and customers as our mission. Also we continue to innovate, join the global high-end manufacturing industry chains, and promote high-quality "Made in China" hardware to the world VALUES: *Quality first *supreme service *honest and pragmatic *customer satisfaction

We focus on the leader in precision cold extrusion process and solutions to reduce manufacturing costs

STANDARD METAL, we are professional solutions provider who focus on hardware consecutive precision cold extrusion technology to solve the industry problems of high cost, low efficiency, difficult processing of high-tech hardware manufacturing.

Technical Features Advantages

Technical Features: 1). High precision molding, fast speed, parts tolerance can be tested within +/ -0.02mm. 2). One time molding without other supporting process. 3). Truly optimize the cost, applicable to Invar, Kovar, copper, iron, nickel, aluminum, stainless steel and other raw materials which are malleable under HV220 hardness degrees can be completed into extrusion molding. STD really solves the angle collapse problems in cold pier and stamping process

We Have The Best Solutions for Your Business

STANDARD METAL has a number of independent intellectual property rights included 12 domestic and international invention patents.

We mainly focus on optical communication, car automotive sensors, industrial automation, precision medical equipments, aviation industrial automatic control hardware, military packaging hardware, consumer electronics hardware and other applications. STD is using high-technology, unique innovation and modern process management to provide highly competitive products and offer professional services to meet customer needs.

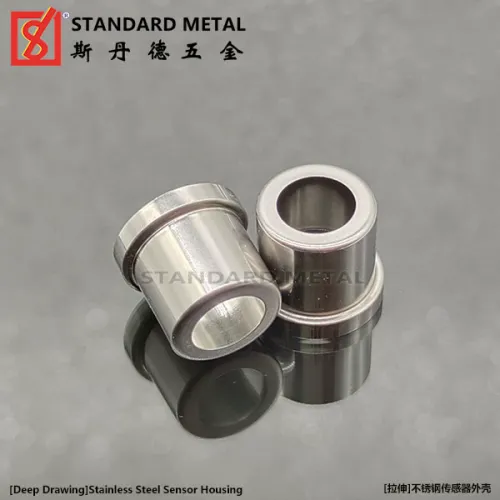

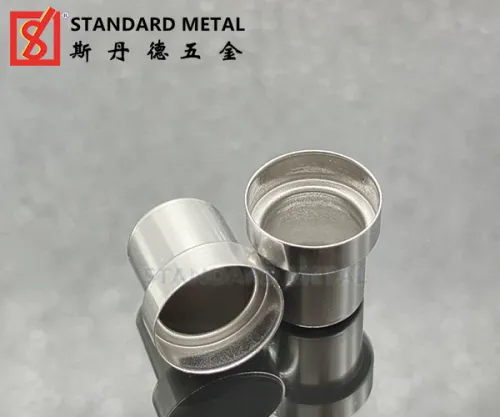

Feasibility of deep drawing part

Deep drawing part is a process that can deform steel plates or other non-ferrous metal materials, and can refer to a process that provides both elongation and compression deformation, mainly for hollow, cylindrical, box-shaped, special-shaped or cup-shaped objects. Deep drawing part of sheet metal parts is carried out through progressive or transfer dies and allows the creation of many objects with deep cavities, including: automotive body parts, household appliances, details for the furniture and electronics industries, various containers such as cans, jars etc.

Steps in the stamping process of deep drawing part

1 Design Consultation: Detailed consultation on part design, including in-depth analysis of part size, material, stretch ratio and resulting beauty

2 Stamping machine selection: Determine the machine size and caliber suitable for the part size and material.

3. 3D Virtual Prototyping: Use virtual software to create prototypes of parts. Run the prototype through extensive operational simulations to uncover any design issues before the production process begins

4. Equipment design: The dimensions and requirements of the components are combined with the die and punch.

5. Deep drawing process: put the raw material on the mold and fix it. Start the press and press the punch against the die with a force of 400 tons. Repeat the process until the components are the desired size and shape.

The benefits of deep drawing part

Deep drawing part are highly versatile and can be used to create complex, detailed parts with unmatched accuracy and repeatability. Additionally, deep drawn parts are exceptionally strong due to the compressive forces exerted on the metal during the forming process. The basic structure of deep drawn metal is usually highly compressed into a very hard crystalline structure.

User Reviews

What users say about Robot

Frequently Asked Question

Do you have any question?

This is one of the most common deep draw problems. Fracturing of the metal during the draw process can be caused by several issues although the most common is the clearance between the punch and the die. If this is too small, too large, or uneven, the material can be cracked during drawing.

All the factors involved in a deep drawing manufacturing process will have an effect on the quality of the part. Sheet metal parts can be tested for formability. Blanks are often printed with a square grid with circles in each grid box. The squares and circles distort with the sheet metal as the process occurs.

Although the finished product might look simple, and no doubt the experts make it look easy, the deep drawn process is actually one of the most complicated methods of manufacturing available. The act of forcing metal into a given shape introduces a host of possible problems and concerns.